Refractory Anchors For Forging & Heat Treating

Forges and heat treatment facilities play a pivotal role in modern society. They produce metals that can maintain structural integrity under extreme stress, a quality that improves the performance of everything from medical supplies to aerospace components. Changing metal characteristics is a complex process involving multiple operations, many of which function at high temperatures and demand increased structural, chemical, and environmental stability.

Delta Stud Weld helps forge and heat treatment facilities reach new levels of safe performance with temperature-resistant refractory anchors for forging and heat treatment sourced and manufactured in the United States of America. By leveraging superb materials and fabrication techniques with industry-specific engineering and project management, we develop custom fastening solutions for the lining and insulation materials meant to defend critical infrastructure and employees from heat and corrosion.

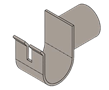

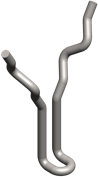

- Refractory anchors

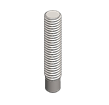

- Studs

- Insulation fasteners

- Welders

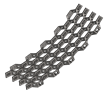

- Steel fibers

- Cable hangers

- Hex steel

Refractory lining is material that acts as a heat-resistant barrier between high- and low-temperature zones. Forges and heat treatment facilities use it to keep as much heat within the forge or furnace as possible, which results in a more efficient heating process. This lining is designed to be a support structure, but it must be secured to a wall to work effectively. That’s why high-quality refractory fastening components are so important.

Forges and furnaces reach extreme temperatures and often operate 24 hours per day to meet the demand for high-performance metals. Refractory hardware must be manufactured from high-quality materials because, being closest to the hot face, they experience the highest temperatures. Also, these parts must prevent wall buckling caused by internal thermal stresses, which can hinder equipment operation and jeopardize personnel.

Delta Stud Weld manufactures all high-temperature refractory anchors for forging and heat treating using a range of resilient stainless steels and nickel alloys sourced from trustworthy domestic mills. All raw material is verified for accuracy, and Material Test Reports are supplied with shipments. We can fabricate products from just about anything, but our specialties are the following material grades.

- 304 stainless steel

- 309 stainless steel

- 310 stainless steel

- 330 stainless steel

- 601 Inconel

- 800 Incoloy

Improve your metal forging and heat treatment processes with refractory hardware from Delta Stud Weld. We are committed to developing quality, heat-resistant fastening solutions for the metal processers that advance societies.

At Delta Stud Weld, we understand every situation is unique, and off-the-shelf items aren’t always ideal. That’s why our facility specializes in quick-turnaround build-to-print services for forges and heat-treatment operators. Whether it’s a vetted drawing or a not-yet-realized idea, our experienced engineering team can take your plan from design to finished product quickly and efficiently.

.png)