Refractory Anchor & Stud Welding For Marine Industry

From intense heat and colossal swells to severe freezes and substantial rain, the maritime industry regularly encounters hazardous environments at sea and in port. Because the weather continually changes and the water contains a significant amount of dissolved salts, infrastructure and assets are particularly susceptible to degradation.

Strengthen marine application performance with stud welding and refractory anchors for the marine industry sourced and manufactured in the United States of America by Delta Stud Weld. We develop tailor-made fastening solutions for lining and insulation materials intended to protect maritime structure surfaces and seafarers from extreme temperatures and corrosion common in the marine industry. The use of excellent materials and trusted fabrication techniques combined with veteran project management and industry-specific engineering ensures that our products stand up to the harshest offshore conditions.

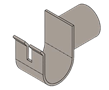

- Refractory anchors

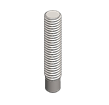

- Studs

- Insulation fasteners

- Welders

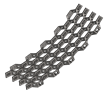

- Steel fibers

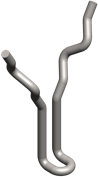

- Cable hangers

- Hex steel

Refractory lining is material that acts as a heat-resistant barrier between high- and low-temperature zones. Marine industry applications primarily depend upon refractories to minimize the loss of heat generated by burning fuel in a furnace. Other uses include fireproofing, rust resistance, and vibration reduction. While this lining is designed to be a support structure, it needs to be secured to a wall to work successfully. This is where refractory fastening components specially designed for offshore environments come into play.

Refractory hardware must be manufactured from high-quality materials because, being closest to the hot face, they experience the highest temperatures. Also, these parts must prevent wall buckling caused by internal thermal stresses, which can negatively impact seagoing vessel or offshore structure operation and endanger key personnel.

Delta Stud Weld manufactures all refractory hardware for the marine industry using a range of resilient stainless steels and nickel alloys sourced from trustworthy domestic mills. All raw material is verified for accuracy, and Material Test Reports are supplied with shipments. While we can fabricate products from just about anything, we specialize in the following material grades.

- 304 stainless steel

- 309 stainless steel

- 310 stainless steel

- 330 stainless steel

- 601 Inconel

- 800 Incoloy

From deck to dock, improving personnel safety and structural temperature and corrosion resistance is simple, efficient, and budget-friendly with Delta Stud Weld refractory hardware.

Our area of expertise is fast-turnaround build-to-print services for the marine industry and its service providers. Whether it’s an approved drawing or an idea that has not yet been fully realized, our expert engineering team can take a plan from design to finished product swiftly and professionally.

We are available to identify the best refractory lining and insulation fastening solution for your maritime application. Contact us today to learn more about our refractory anchor & stud welding for the marine industry.

.png)